Sysav Heat and Power Plant

Project: New building

Our delivery: 2008

- Facade cladding systems

- Design profile S55

Partners:

- main contractor: NCC

- Subcontactor: Plåtexpressen

Galvaniser and painted sheet metal

From drawing board to construction

Initially, the main contractor (NCC) only had an architect’s draft, and the subcontractor (Plåtexpressen) faced a number of challenges.

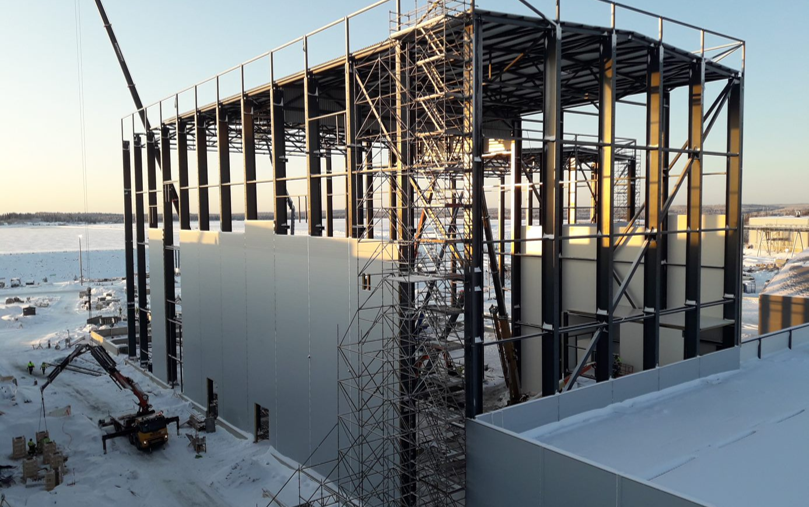

The roof of the power station was to house a weather shield, containing insulation, and a frame to hold the shield at the right angles and dimensions. Wind and weather loads were important factors in the calculations, for ensuring a functional system.

There were also stringent requirements for the interior walls due to stress caused by heat and moisture. In turn, as with the roof, the exterior walls also had to withstand the elements.

Furthermore, the construction also had to be rational in terms of price and time consumption.

Two stages

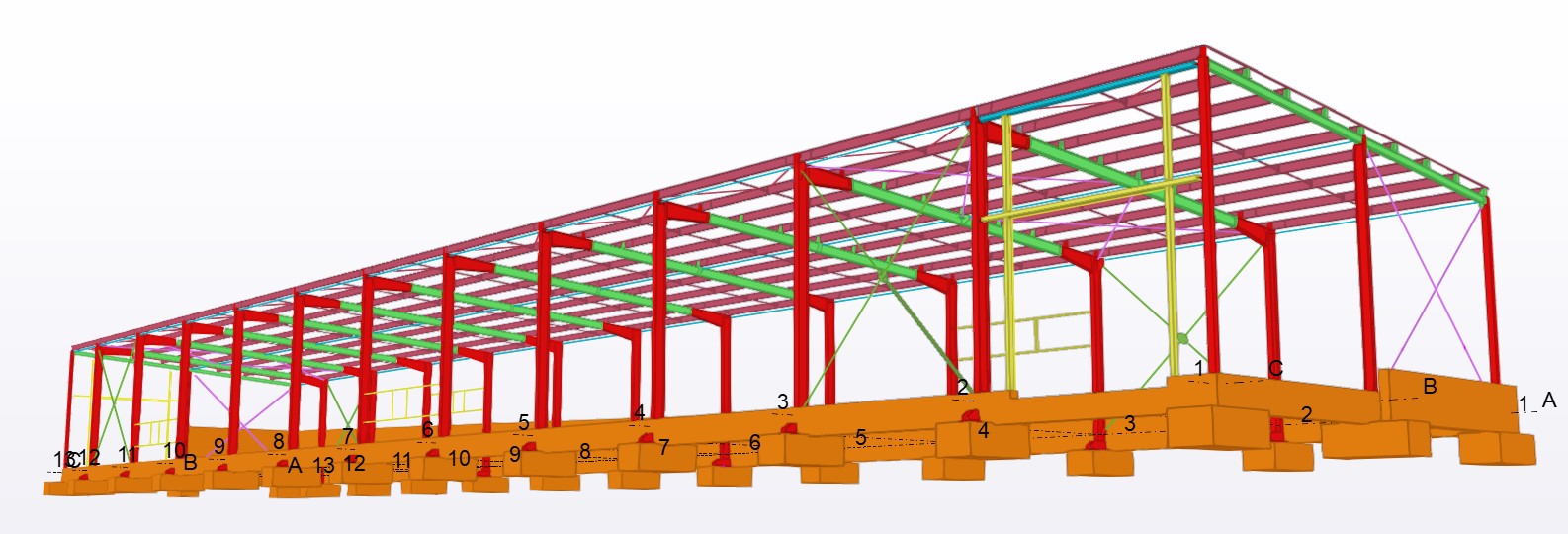

Most of the technical solutions had to be installed during the first of the two stages in which Sysav was built. The challenges Ruukki faced were the detailed design of the roof and walls, the drawings and turning the architect’s drawings into practical solutions.

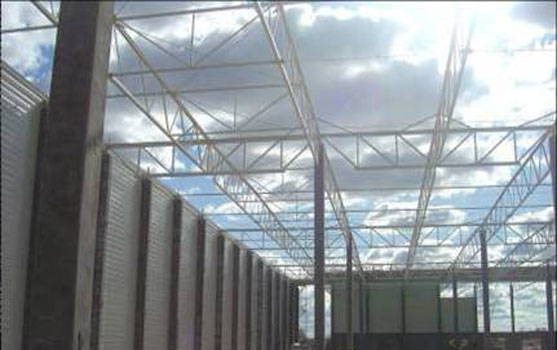

The roof required a weather shield and a structure to hold it up. On a tall building in an exposed and often windy location, if the weather shield was to work, getting the dimensions exactly right was extremely important. The walls also had to act as weather shields, and in this regard the architects had a clear vision of their final appearance, with a horizontal sinusoidal profile.

Galvanised and painted sheet metal

For the walls, Ruukki used a raw aluminium horizontal sinusoidal profile, the Sinus 55. It is seawater resistant and glossy to begin with, but it turns grey over time as a result of oxidization. Behind this they placed a bracket and a 1.2 mm sheet metal inner wall. The sheet metal was galvanised and coated with a paint usually used for exterior walls, as the surface had to be resistant to the heat and moisture of a power/heating plant.

Ruukki produced the technical solutions for the walls and roof in cooperation with the structural engineers, Ramboll. “We sat down and resolved all the details together and then based the drawings on that,” explains Gunnar Gundersen, Ruukki’s Sales Engineer.

An obvious choice

“We have worked with Ruukki for a long time, and they were the obvious choice for us in this project, too,” says Henry Svensson, CEO of Plåtexpressen, Ruukki’s client for the Sysav building.

Ruukki was a fantastic partner in always keeping to deadlines and in offering very good prices. “Ruukki is highly competitive and can supply more or less anything when it comes to sheet metal,” says Svensson.

Ruukki supplied an IP bracket, which is a steel construction and was used as wall insulation. They also supplied the sinusoid aluminium surface sheeting and the corrugated steel (TRP steel) for the roof. “It was of a high quality, and we were finished on time. When you’re building something 50 metres high, it is important that everything arrives on time and in the right order,” says Svensson.

Good value and rational

Initially, the price of prefabricated wall brackets can be higher than other methods. With major construction projects, the time aspect is extremely important for the price. “It’s a question of carrying out the construction rationally, as this affects both the price and the time consumption, and the overall benefits are then greater using this model,” says Gundersen.

Ruukki employees are experts in construction solutions and in addition to high quality and delivery reliability, Ruukki will also assist in developing the practical solutions and implementation.

The references shown are only a small part of the projects we have done, and the most recent ones are yet to come.

Are you interested to know more, please contact us!